China’s Fastener Industry Hubs: The Backbone of Industrial Production

Fasteners, commonly known as screws and nuts, are fundamental mechanical components often referred to as “industrial rice.” From aerospace shuttles, automobiles, and machinery to tables, chairs, and benches, fasteners are ubiquitous. This industry is labor-intensive, capital-intensive, and strategically important as a high-tech sector, receiving significant attention from governments worldwide. After years of development, China has emerged as the world’s largest fastener producer.

Currently, China boasts nearly 10,000 fastener manufacturing and trading enterprises, employing over 1 million people and making substantial contributions to employment. Carbon steel fasteners produced in China are primarily used in furniture hardware, electronic products, electronic equipment, machinery, construction, and general industrial applications. Looking at China’s production regions, the fastener industries in Yongnian, Wenzhou, and Haiyan have developed the most extensive scale and distinctive characteristics.

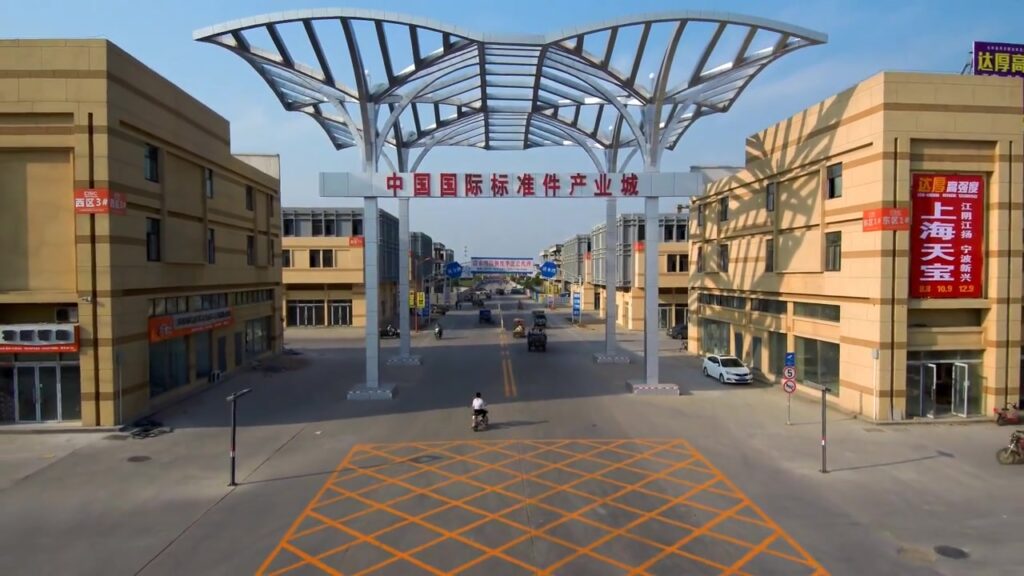

01 Yongnian District, Handan City

Honored as the “Capital of Chinese Fasteners,” Yongnian is China’s largest fastener production and distribution center. It’s recognized as a national-level small and medium enterprise specialized industrial cluster, a national foreign trade transformation and upgrading base (fasteners) certified by China’s Ministry of Commerce, and one of the provincially-supported county-level specialized industrial clusters.

The district can produce all 12 major categories and 289 subcategories of products specified in the “National Standard Catalog of Fasteners.” These products are widely applied in home furnishing, automotive, high-speed rail, power, mechanical, and other fields. In 2023, the district’s fastener production reached 6 million tons with an output value of 42 billion yuan, accounting for approximately 58% of China’s market share and 28% of the global market.

Yongnian’s fastener industry has a long history and solid industrial foundation. As early as the Spring and Autumn Period, the ancestors living in Yongnian established connections with “standard parts.” During the Anti-Japanese War, the region secretly repaired and manufactured firearms for the anti-Japanese front, giving birth to Yongnian’s first screw. After the founding of New China, Yongnian’s standard parts industry gradually transformed from agricultural production services to modern industry. Following the Reform and Opening Up, standard parts workshops flourished throughout Yongnian, with various processing enterprises emerging like bamboo shoots after rain, reaching nearly 10,000 at its peak.

02 Wenzhou City, Zhejiang Province

Wenzhou’s fastener industry began in the 1970s. After nearly 30 years of development, Wenzhou now has more than 3,000 fastener and related upstream and downstream enterprises, plus approximately 10,000 business operators distributed throughout China. Of these, more than 200 enterprises have achieved significant scale and quality. Annual production reaches over 1 million tons with an output value of approximately 10 billion yuan, accounting for about 30% of China’s market share.

Recently, a Wenzhou company obtained a patent for “waterproof fasteners.” By creating installation grooves on nuts and setting waterproof rings, the product effectively enhances the sealing effect between components, improving waterproof performance and preventing rainwater from penetrating into threaded holes—a shining example of fastener industry innovation.

03 Haiyan County, Zhejiang Province

Haiyan, known as “Iron Haiyan” and the “Hometown of Fasteners,” has traditionally been led by the fastener industry. Currently, Haiyan County has established four major fastener industrial clusters: Development Zone, Qinshan, Yucheng, and Zhouzhuang. The county has over 700 standard fastener manufacturers, including more than 150 large-scale enterprises. They primarily produce approximately 14,000 varieties of products including general standard fasteners, threaded rods and nuts, screws, and high-strength long-bolt series. The annual output value reaches over 13 billion yuan, with upstream and downstream enterprises in the industry chain achieving main business revenue of over 17 billion yuan—accounting for one-quarter of the provincial total and approximately 10% of China’s market share.

Keeping pace with “China Speed,” critical components for China’s new generation of “Fuxing” high-speed trains—including brake discs, gearboxes, couplers, and seat supports—come from a Haiyan enterprise. Currently, fastener giant Chin Jig Industry is located in Haiyan, Zhejiang. Leading enterprises often play an excellent driving role in promoting the rapid development of small and medium-sized fastener enterprises.

Additionally, public service platforms related to the fastener industry are relatively well-established, including national professional fastener markets, national-level fastener testing centers, and fastener surface treatment centers, forming a relatively complete industry chain from raw material supply and product manufacturing to equipment production.